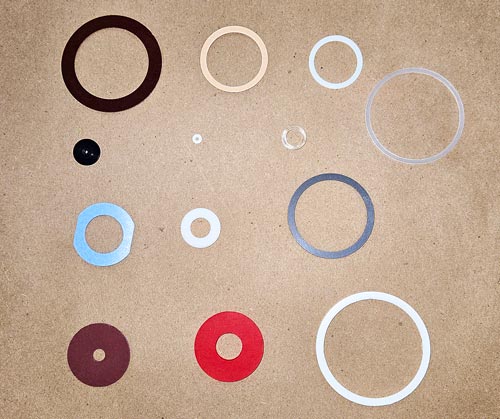

Custom and specialty rubber and plastic washers are precision-made sealing components that are manufactured to your specifications. Whether it’s unique profiles, specific material properties, or extremely close tolerances, we manufacture specialty washers in plastic and rubber that will deliver the exact performance you need.

Our custom non-metallic washers are found in various industries worldwide for several functional purposes. They are used for general sealing & gasketing, vibration dampening, electrical insulation, weather sealing, and other uses.

Custom Rubber Washers

We die-cut and machine custom rubber washers to your exact specifications. We leverage our extensive in-house inventory of dies to eliminate or significantly reduce tooling costs for most jobs.

Rubber Washer Materials – We utilize commercial-grade or Mil-Spec materials, all sourced from trusted suppliers. Our custom rubber washer material offerings include, but are not limited to, the following:

- Custom Neoprene Washers

- Nitrile/Buna-N Washers

- Silicone Washers (including FDA compliant materials)

- EPDM Washers

- Fluorosilicone Washers

- NSF/EPDM Washers

- Viton Washers

- Other non-metallic materials available, contact us for details

Custom Plastic Washers

We fabricate custom plastic washers from a variety of materials exactly to your needs. We help keep tooling costs in check for plastic washers by leveraging our many in-house dies.

Plastic Washer Materials – Washers are made from commercial or Mil-Spec grade materials, we produce:

- Custom nylon washers

- Custom Teflon®/PTFE Washers

- Other fluoropolymer plastics

Custom Washer Manufacturing Capabilities

Rubber & Plastic Washer Applications

Our custom rubber and plastic washers are used in many common and specialty applications and industries wherever there is a need for quality, consistency and superior performance. They include the following:

- Automotive – Fuel systems, engines, transmissions, braking systems

- Aerospace – Hydraulic systems, fuel lines, environmental seals

- Food & Beverage – Processing equipment, packaging machinery, dispensing systems

- Medical/Pharmaceutical – specialty equipment, drug manufacturing, medical devices

- Oil & Gas – Pumps, valves, pipeline connections, drilling equipment

- Marine – Saltwater-resistant sealing, boat hardware, offshore equipment

- HVAC – Chillers, boilers, ductwork, refrigeration systems

- Industrial Manufacturing – Assembly line equipment, hydraulic presses, conveyors

Custom Rubber & Plastic Washer FAQs

Yes. We have on-site kiss-cutting capabilities which allow us to do exactly that for both rubber and plastic washers.

We can reliably deliver washers with tolerances as tight as +/- .002″. This is due to our stringent quality control processes, and with the help of our precision in-house die-cutting capabilities and CNC equipment.

Absolutely. Simply send us your sample or technical drawing, and we’ll reverse-engineer it to manufacture to exact replacements. In certain cases, we are able to recommend and make improvements.

Delivery times will vary depending on the requirements and are based on a few factors. These include material availability, complexity, and quantity, among others. Since we maintain a deep in-house inventory of dies, we can produce and ship many orders out the door faster than others. Reach out to us with your specs for a timeline.

Custom washers are made to customer specs for specific shapes, sizes, materials, thicknesses, and tolerances. Conversely, standard washers are mass-produced in common sizes and may not provide the exact fit or material properties needed. Custom rubber and plastic washers are designed for each use to ensure optimal sealing, vibration dampening, or insulation.

We can handle prototype to full production runs into the thousands and millions.