Elastomers are found just about everywhere. It’s no wonder, since they are very versatile materials. This is primarily due to their high viscoelasticity, meaning they are both viscous and elastic when under pressure. As you can imagine, these properties make elastomers an ideal material choice for non-metallic washers and gaskets. They can “flow” just enough to fill the gaps, but they can also push back to maintain a tight seal. But there are many elastomers available on the market today, so it’s important to select the ideal one for a particular use.

Choosing the right elastomer ultimately comes down to matching the demands of the application such as temperature, fluid exposure, and pressure, with specific material properties, such as chemical resistance, hardness, and abrasion resistance. For certain industries, compliance requirements also come into play, such as those maintained by UL for electronics or the FDA for food, beverage and pharmaceuticals.

So, to choose the ideal one, you have some work to do. You’ll need to define operating conditions, identify mechanical demands, verify chemical compatibility, check for necessary certifications, and of course, consider the cost.

Key Factors to Consider

Let’s take a closer look at selection criteria:

Temperature – high/low extremes, thermal cycling, and potential excursions.

Fluid Compatibility – Exposure to oils, fuels, acids, alcohols, or specific industrial fluids.

Mechanical Demands – static vs dynamic, compression, tension, abrasion, tear, flexing.

Pressure – operating range, vacuum conditions, and pressure changes

Environmental Factors – UV, ozone, moisture, and contaminants

Industry Standards/Certifications – FDA, UL, aerospace, or other required standards.

Cost – evaluate material cost vs performance life, considering that complex formulations may perform better, but cost more

Next Steps

Now that you’ve identified the requirements, including service conditions, you must shortlist the candidate materials. This is where elastomer selection charts come in handy, as they compare various performance characteristics of different materials. You can also ask your supplier for their recommendations. Chances are, they’ve already dealt with a similar set of requirements.

Once you have narrowed down your selection, it’s time to prototype and test, test, test! Ideally, you should test under real-world conditions, especially for critical seals. If this can’t be done, be sure to replicate those conditions as close as possible when testing. Again, for complex needs, we strongly suggest you work with an engineer or manufacturer that has excellent materials knowledge. Doing so will help minimize surprises when you put those gaskets and washers into service.

Common Elastomers and Their Typical Uses

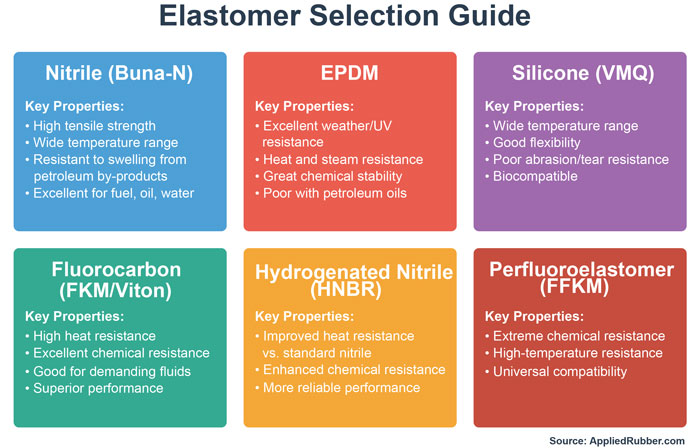

In order to service a wide variety of performance demands, many elastomers are available today. Here are some of the more popular ones, along with their typical applications:

Nitrile (Buna-N) – high tensile strength, wide temperature range, and resistant to swelling when exposed to petroleum by-products making it excellent for fuel, oil, and water applications (e.g., automotive fuel systems).

EPDM – excellent weather/UV resistance, as well as heat and steam, with great chemical stability. This makes it good for steam, water, ozone, and weathering; poor with petroleum oils (e.g., outdoor seals, steam sterilization).

Silicone (VMQ) – Wide temperature range, good flexibility but poor abrasion/tear resistance (e.g., high/low temps, food contact).

Fluorocarbon (FKM/Viton) – High heat and chemical resistance, good for demanding fluids (e.g., aggressive chemicals, engine seals).

Hydrogenated Nitrile (HNBR) – improved heat and chemical resistance when compared to nitrile, making it ideal for more reliable fuel/oil seals

Perfluoroelastomer (FFKM) – extreme chemical and high-temperature resistance (e.g., aerospace, extreme chemical processing).

Conclusion

As you can see, properties of elastomers greatly vary from one to the next. This makes material selection a critical success factor when designing gaskets and washers for specialty uses. Make sure you fully understand the demands of a particular application, review your options closely, and test. Doing so will help ensure that you create reliable seals that will perform as expected.